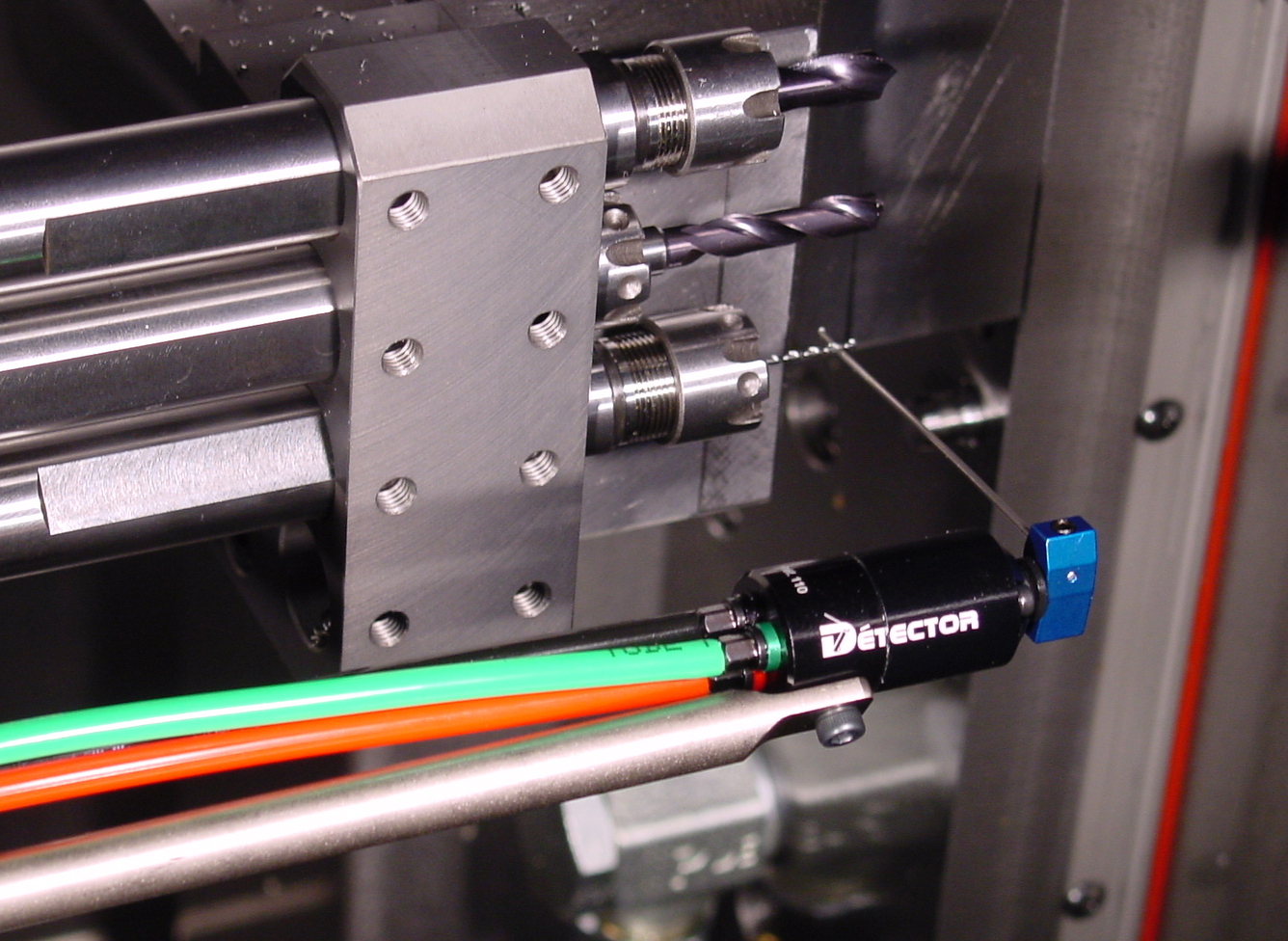

THE SMALLEST ROTARY VERSION ON THE MARKET!

Type 110

Broken Tool/Part Presence

MINI Detection System

The Type 110 is a super miniature probe designed to contact a drill, reamer, or tap when it retracts to its start position or verify part presence before machining. It is particularly suitable for use on small multi-spindle automatics, transfer and CNC machines with quick response during fast cycle times and for very small tools. The probe is very compact (5/8" x 2") and mounts parallel to the drill being checked. It includes articulating fixing rods (similar to an indicator bracket) for mounting at any angle in a crowded tooling area. Two small air lines are required for activation and sensing.

The wand style

probe is air operated. A pneumatic signal

is sent to the probe via an electric servo-valve or a roller

valve on the machine camshaft. If the

wand completes its stroke (in the

case of a broken tool, missing part), then a

pneumatic signal is transmitted to a

pressure switch which is used to

stop the machine or activate any

desired response.

The pneumatic probe has no electrical motor or connections in the work/tool area and the positive pressure activation allows for the purging of coolant and chips every cycle to reduce the need for periodic maintainance. It is truly designed for production machines.

SPECIFICATIONS

Detector

Type 110

Super

Mini Rotary Broken Tool Detection System

PROBE:

- Model

Type 110 for Broken Tool

Detection

- Range:

126o Stroke

- Sensitivity:

Drill diameter over 0.5 mm

(0.020")

- Reaction

Time 0.05 seconds

- Approximate

Size: 16 mm (5/8")

diameter x 51 mm (2")

long

- Designed

for use in production

environment.

ACTUATOR:

- Operating

Pressure 5 bars (75 psi)

minimum

- Customer

provides pneumatic signal

via Roller Valve on camshaft

or via servo-valve from

machine control.

DETECTOR:

- Probe sends

pneumatic signal to electric

pressure switch (included)

when stroke is completed

(broken tool).

- Pressure switch

provides normally open and

normally closed contacts for

connection in parallel with

a machine stopping or other

circuit.

PRICE INCLUDES:

- Type 110 Detector, electric pressure switch,

adjustable universal fixing rods and yoke, spring for

reversing rotational direction, spare feeler wire.

PRICE:

Call for current prices.

OPTIONAL

INSTALLATION KITS:

- Mechanical Type

- Electrical Type

DELIVERY:

Stock, subject to prior sale.

TERMS: Net

30 days, subject to credit approval.

WARRANTY:

Defective Parts & Labor for 3

YEARS.

User can

return in 30 days for full credit if

unsatisfied for any reason (must be

in like new condition).

TOP OF

PAGE Revision 309